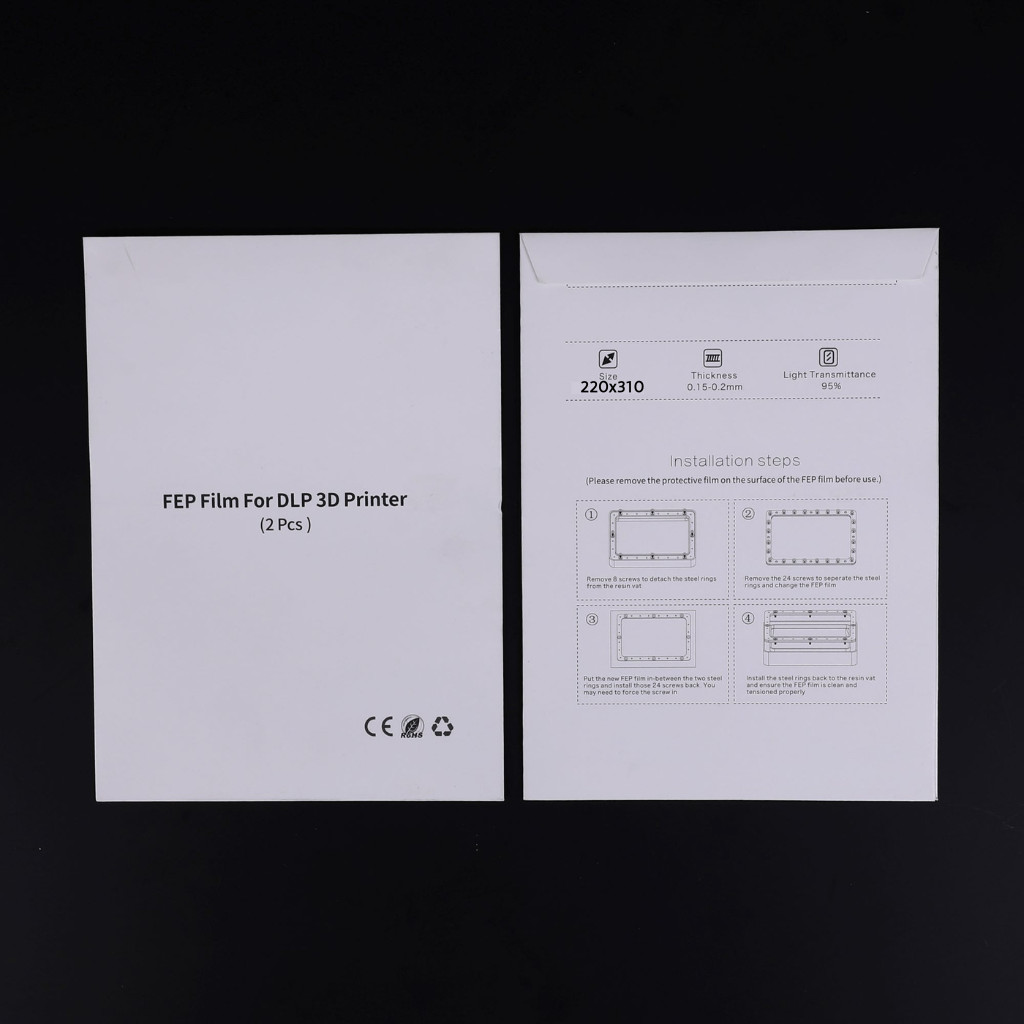

NFEP Release Film – 220mm x 310mm for LCD & DLP 3D Printers

The NFEP Release Film (220mm x 310mm) is engineered for LCD and DLP 3D printers with larger molding formats. Built with advanced materials, it offers low release force, high UV transparency (95%), and excellent temperature resistance. Ideal for 8.9-inch and above light-curing printers.

TCI FEP Fluoropolymer Extruded Films

Thermal range:

Size Mm

Revolutionize Your 3D Printing with NFEP Release Film

The NFEP Release Film (220mm x 310mm) is the ultimate upgrade for your LCD and DLP 3D printers. Crafted with premium materials imported from Japan, this release film enhances precision, durability, and overall printing quality, making it indispensable for professionals and hobbyists alike.

Key Features

1. Low Release Force

The film has a smaller release force than traditional FEP films, ensuring a smooth printing process and minimal adherence of printed models.

2. Advanced Material Composition

Made from a copolymer of tetrafluoroethylene and perfluoroalkyl vinyl ether (PFA), it provides superior non-stickiness and durability.

3. High UV Transmittance

With 95% or higher UV light transmission, the film enhances curing accuracy for better print quality, especially for 8.9-inch+ format printers.

4. Exceptional Temperature Resistance

The NFEP Release Film can withstand extreme temperatures ranging from -254°C to 300°C, ensuring stability and preventing deformation during extended use.

5. Wide Compatibility

Designed for use with LCD and DLP 3D printers, it supports a large printing area of 220mm x 310mm, making it perfect for a variety of applications.

6. Smooth and Non-Sticky Surface

The film’s surface resists adhesion, preventing models from sticking and ensuring easy removal without compromising quality.

Applications

The NFEP Release Film is ideal for the following industries:

- Jewelry: Producing intricate designs with high precision.

- Dental: Crafting accurate dental molds and prototypes.

- Prototyping: Creating detailed models for product development.

- Engineering: High-resolution mechanical parts and components.

Benefits of Using NFEP Release Film

- Enhanced Print Quality: Reduces sticking and increases model accuracy.

- Durability: Resistant to wear and tear, ensuring long-term use.

- Wide Format Support: Perfect for large-format LCD and DLP printers.

- Easy Maintenance: Non-stick surface makes cleaning and model removal effortless.

- UV Optimization: Maximizes UV light penetration for faster curing times.

Why Choose NFEP Release Film?

This NFEP Release Film is a game-changer for users seeking higher resolution and smoother printing processes. With its advanced material properties and superior performance, it’s the perfect choice for professional-grade 3D printing projects.

FAQs

Q: What printers is this film compatible with?

A: The NFEP Release Film is compatible with LCD and DLP 3D printers with a molding size of 220mm x 310mm or larger, especially 8.9-inch+ printers.

Q: How does it compare to FEP release films?

A: NFEP offers a lower release force, higher UV transmittance, and better temperature resistance, making it a superior choice for precision printing.

Q: Is it easy to replace the release film?

A: Yes, the NFEP Release Film is designed for easy installation and maintenance, ensuring a hassle-free replacement process.

Explore our LCD and DLP printer accessories.