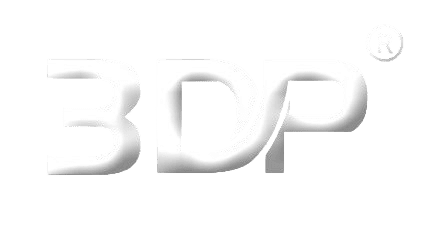

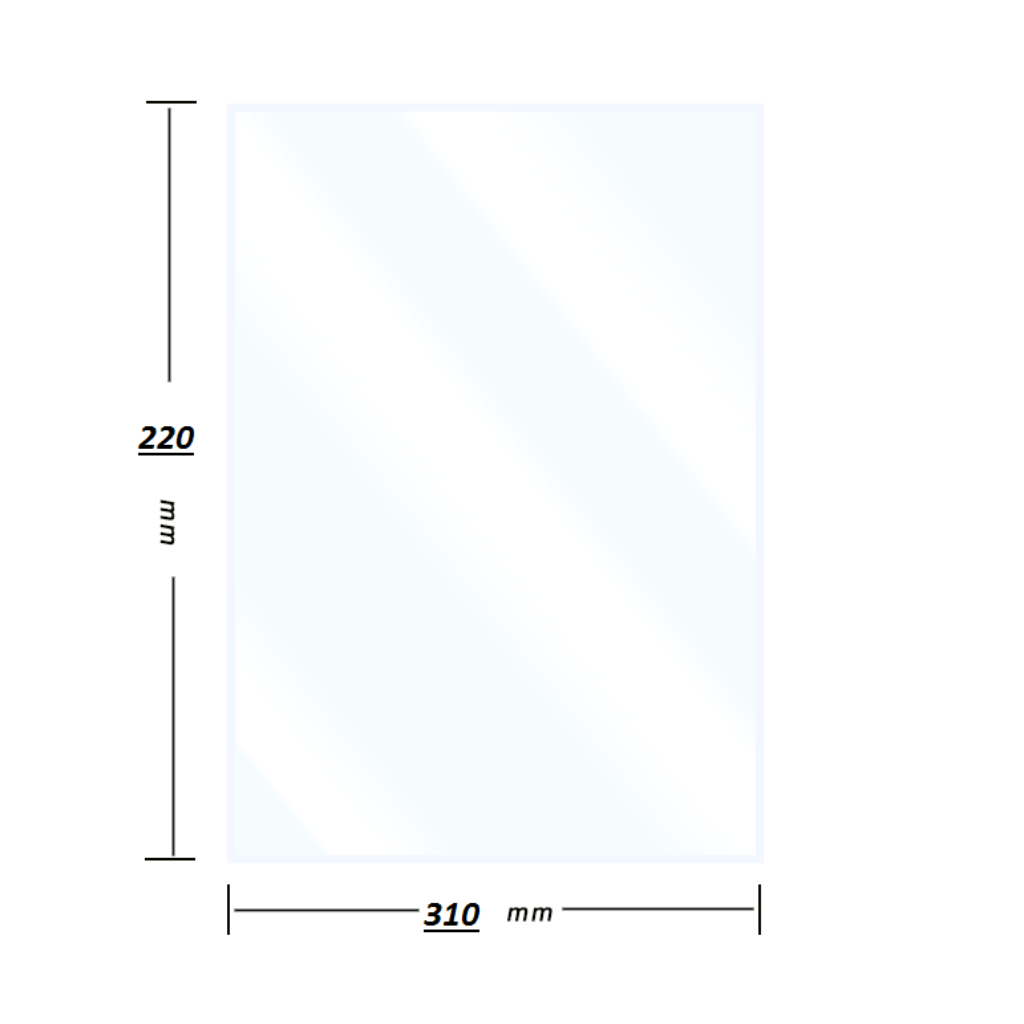

FEP Release Film for LCD & DLP Printers – 220mm x 310mm

Enhance your LCD and DLP 3D printing with the FEP Release Film (220mm x 310mm). Designed for large-format printers, it offers high UV transmittance (≥95%), excellent durability, and effortless model release, ensuring consistent and high-quality prints.

no warranty no guarantee Fep Film

Fep sheets offer resistance to different chemicals due to their

fluoropolymer content. It is not universally resistant

to every chemical but still could be …

FEP stands for Fluorinated ethylene propylene, which means fluorinated ethylene propylene copolymer (perfluorinated ethylene propylene copolymer).

FEP release film has excellent temperature resistance, corrosion resistance, non-stickiness and high light transmittance. These characteristics enable FEP release film to play an important role in the 3D printing process.

Description

Enhance your 3D printing projects with our FEP Release Film for LCD and DLP Printers. Specially designed for larger build platforms, this release film delivers superior transparency, low release force, and high heat resistance. Crafted from durable Fluorinated Ethylene Propylene (FEP), it ensures long-lasting performance and flawless 3D prints.

Key Features

1. High UV Light Transmittance

- Achieves over 95% UV transmittance, enabling faster curing and more accurate 3D printing results.

2. Large Format Dimensions

- Sized at 220mm x 310mm, perfect for 8.9-inch and larger LCD and DLP printers.

3. Exceptional Durability

- Withstands prolonged exposure to high temperatures and chemicals without compromising quality.

4. Effortless Model Release

- Features a smooth, non-stick surface for easier removal of printed models.

5. Wide Compatibility

- Works with most LCD and DLP 3D printers, making it suitable for a variety of applications.

Applications

The FEP Release Film for LCD and DLP Printers is perfect for:

- Prototyping: Create precise, functional prototypes for product development.

- Jewelry: Print intricate and detailed designs with ease.

- Dental Applications: Achieve accurate molds and prosthetics for professional dental use.

- Engineering: Produce reliable, functional components for technical applications.

Benefits

- Efficient Printing: Achieve flawless curing and intricate detailing.

- Durable Material: Extended lifespan ensures cost-effectiveness.

- User-Friendly: Simplifies post-processing and model removal.

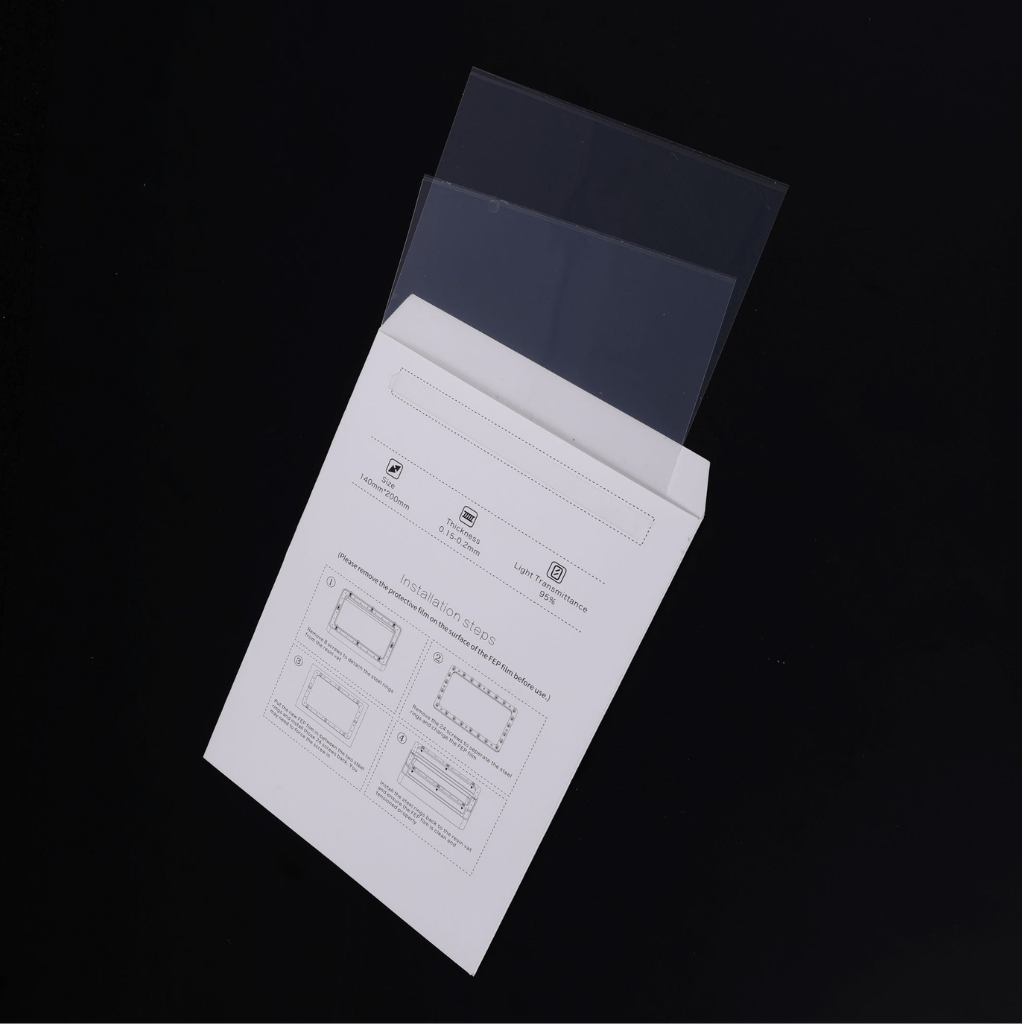

How to Use

- Remove the old release film from the resin vat.

- Clean the vat thoroughly to ensure no residue remains.

- Place the new FEP Release Film evenly, ensuring no wrinkles or bubbles.

- Tighten the screws uniformly for proper tension and alignment.